Audio Topics

AUDIO TIPS you can try at HOME!

All About Tape Head Wear and Re-lapping

All About Tape Head Wear and Re-lapping

SOME USEFUL AUDIO TEST SOUND SOURCES

By Ben Solomon, Owner and Chief Technician at Thin Air Audio, LLC

General rules when checking the sound quality of an audio system by ear:

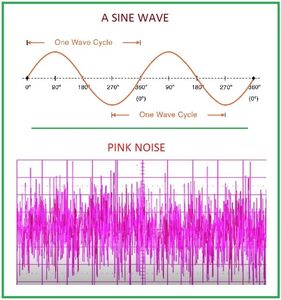

If you're checking for distortion, a pure sine wave, or sinusoid, is the best source because our ear can detect surprisingly low levels of Total Harmonic Distortion (THD), which is one of the most commonly considered types of audio distortion. The definition, or derivation, of a sine wave is that its the one special wave pattern for which 100% of its energy is at ONE frequency; by definition, harmonic distortion is any energy that exists in the signal that is not at the primary or fundamental frequency. This characteristic reveals an audio path's non-linearity, which is a measure of how much the output waveform deviates from a pure sine shape. 400 Hz (one Hertz is equal to one cycle per second) is a popular frequency because it's near the peak of our ears' sensitivity and it's not too shrill or ground-shaking.

Just google "400Hz sine wave" for a sound file with such a waveform, like the one at https://www.youtube.com/watch?v=vuhvAgxDsUY.

NOTE that you need to be careful not to turn the gain up to or past the point of clipping, unless, of course, you're testing to see the amount of signal where an amp or channel begins to clip!

On the other hand, if your object is to do a quick check of the entire audible frequency spectrum all at once, the best choice is pink noise. That's because pink noise (as opposed to white noise that contains equal energy per Hertz) contains equal amounts of sound power or energy within each octave (frequency ratios 1:2 or 2:1) of the frequency spectrum, which is more like the way we hear. For instance, with a pink noise source, the range of the octave from 100 to 200Hz contains the same amount of sound energy as the octave from 200 to 400Hz or 1,500 to 3,000Hz (this is one reason why the filters in a graphic equalizer are usually set to 1, 1/2 or 1/3 octave ranges). Pink noise provides a quick and convenient way to instantly compare, for example, the frequency response of two different channels or the effect of EQ settings of an equalizer circuit in say, a mixing board, This is also a very good method to get a quick idea of how close the frequency response of a tape recorder is to "flat". As mentioned above about using a sine wave, be careful not to clip the signal! Google "pink noise" for a sound file to use as a test source, https://www.youtube.com/watch?v=6ZEFb6Zi3sI for example.

All About Tape Head Wear and Re-lapping

All About Tape Head Wear and Re-lapping

All About Tape Head Wear and Re-lapping

The Physics of Tape Head Wear and Re-lapping

The difference between a re-lapped head and one that's simply worn, can be subtle.

The tape contact surface of a worn head will be perfectly flat. A properly re-lapped head, on the other hand, will be contoured slightly to approximate that of a new head so the tape will contact a relatively small area to each side of the gap (head center line).

Following the basic physics principle of pressure equals force exerted over area, or P=F/A, you can see that if the head face is flat (worn) over a relatively large area, the available force is spread out over a much larger area than when the head was new. This greatly reduces the pressure at the critical point - the gap where the magnetic flux is being picked up during playback or put down during recording. So, any small irregularities in the tape surface which would not be likely to be noticed with a new head, will be much more likely to result in a dropout.

So, is there a limit to how many times a head can be re-lapped? That depends on the remaining usable thickness of metal in the area to be re-lapped. This, then, is affected by the construction of the head and whether any cavities (bubbles) in the metal may exist beneath the surface that would cause irregularities in the re-lapped surface.

--------------------------------------------------

WHAT'S THE BUZZ?

Could those noises you’ve been hearing occasionally in your audio equipment be caused by something other than the equipment itself?

Have you ever heard a rhythmic buzzing, clacking or ticking sound in your stereo, PA system or guitar amp? If you have, it may not be the fault of your audio equipment. This kind of unwanted noise in audio devices can be caused by digital communications interference. The technical name for it is GSM, short for G(lobal) S(ystem for) M(obile communications, which is the radio frequency technology your cell phone communication is based on.

Do you think there might have been a cell phone near the unit while you were experiencing the noise? Phones typically produce that type of interference periodically whenever they're on, whether or not you happen to be talking on the phone or surfing the internet.

On the other hand, if you hear unwanted noises - buzzes, hum, pops, hissing - in your amp or audio system when there are no powered-up cell phones or other electromagnetic noise generating devices operating nearby, we'll be glad to take your gear in and evaluate the source of the noise and eliminate it. We at Thin Air Audio, LLC service all kinds of audio equipment.

Thin Air Audio Repair is your Go-To Source for ALL your Audio and Musical Electronics Repair Needs.

And remember that ALL SOUND IS CREATED OUT OF THIN AIR!

--------------------------------------------------

KEEP THOSE CONTROLS AND SWITCHES QUIET - USE IT OR LOOSE IT!

The purpose of this article is to make you aware of a simple thing that can be done to help keep your pots and switches in good working condition - and it's something you can do YOURSELF without calling the local tech!

Think of the last time you had to take your mixer (amp, receiver, tape deck, etc.) to the shop because of noisy or intermittent controls and switches.

Now think of how long it had been since you'd used that piece of gear before you noticed the problem and had it serviced - or worse yet, tried to fix it yourself! Do you notice a pattern?

The reason these components get messed up in this way is kind of like what happens when you try to clean off the top of that dresser you’d been storing in your garage for a year and a half. First, you might try to dust it off with a feather duster, but your heart sinks when you find that that only removed the more recent surface dust and there's still a layer of older dust that's been hardened by moisture and air pollutants.

That's what happens to the conductive contacts inside your pots and switches when your gear sits unused for a long period of time. Dust and pollutants combine with moisture to form an uneven, electrically insulating barrier between the contact points in a control or switch. The result? - noise, dropouts and scritchy-scratchiness in your earbuds, speakers or recordings!

(Note that software controls - like the volume control on your modern home theater system - don’t suffer from this problem because there are no physical connections involved)

Usually, ALL YOU NEED TO DO TO PREVENT THIS is to occasionally, say once a month, move all the controls and switches through their range several times. Keep in mind that this same idea applies to gear that you’re not currently using.

Another good reason to do this kind of self preventive maintenance is that restoring the operation of these components is one of the most TIME CONSUMING (= expensive) tasks I perform in my shop as accessing those parts to clean with special cleaners can be hard to do. It's difficult because they tend to be buried deep inside the unit and the degree of disassembly can often be extensive.

What this means to you, especially if there are other problems with the gear, is that a little of this simple self-maintenance can SAVE YOU UP TO 50% off the total labor charge! I'm just sayin’...

--------------------------------------------------

Trouble From Circuit Boards Not Made With Plated-Through Lead Holes

Here are pictures (you may need to zoom in to see the detail) from a Tascam Model 38, 1/2" 8-track reel-to-reel repair in which we found multiple deteriorated solder connections that caused multiple bad and intermittent connections to the point where the machine was unusable.

If the circuit boards in your machine happen to be made the same way - without the plated-through holes that would make it very unlikely that the connections would ever go bad - it's possible that some of these unreliable connections could exist and cause failures. In this case we had to completely tear down the machine to gain access to re-solder the bad connections!